Manufacturing industry

Yamaha Motor Iwata South factory

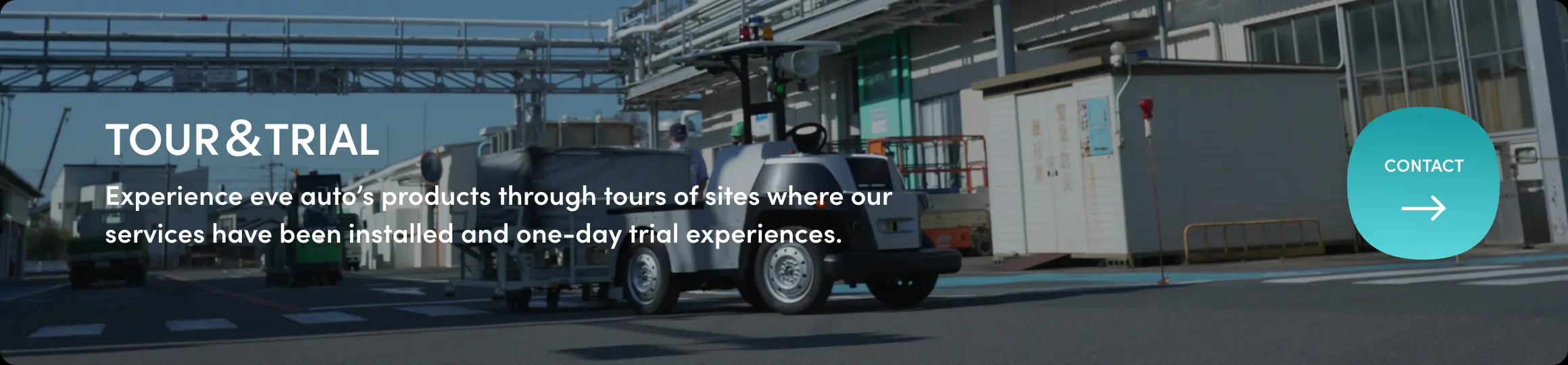

Outdoor transport between forging process and machining process

Customer’s requests

Customer’s requests

- Conveyance by several vehicles at the same time

- Implementation by lower initial investment

- Operation including several points of pick-up and drop-off

eve autonomy’s solutions

eve autonomy’s solutions

The object of automated conveyance is 1.2 tons of parts. It is used for a 1400m outdoor route on the field with running vehicles such as trucks, forklifts and container cars. “Detection Area” (*) function helps smooth operation without any additional equipments such as signals. The routes are flexibly switched by scheduling function of the fleet management system

* Detection Area is the area to detect obstruction as it can be set arbitrarily on the 3D map.

Customer’s comments

Customer’s comments

As the 1st step, we tried to replace in-house logistics by trucks because it was easy to imagine the new opration. Once started the trial, we found it’s necessary to change the positions of truck yard and storage space. It was very tough for a long time because of various arrangements with related parties rather than automated conveyance itself. However, the system provided by eve autonomy is really easy to change the route, and it helps us a lot since we revise the plan many times. Now we conceived of the new use case which we did not expect at the beginning, for example, the data of conveyance can be used for a kind of pacemaker at the production line between working areas. We are seeking the better route to be more effective.

Other cases