Manufacturing industry

Panasonic Corp., cold chain factory in the Oizumi area

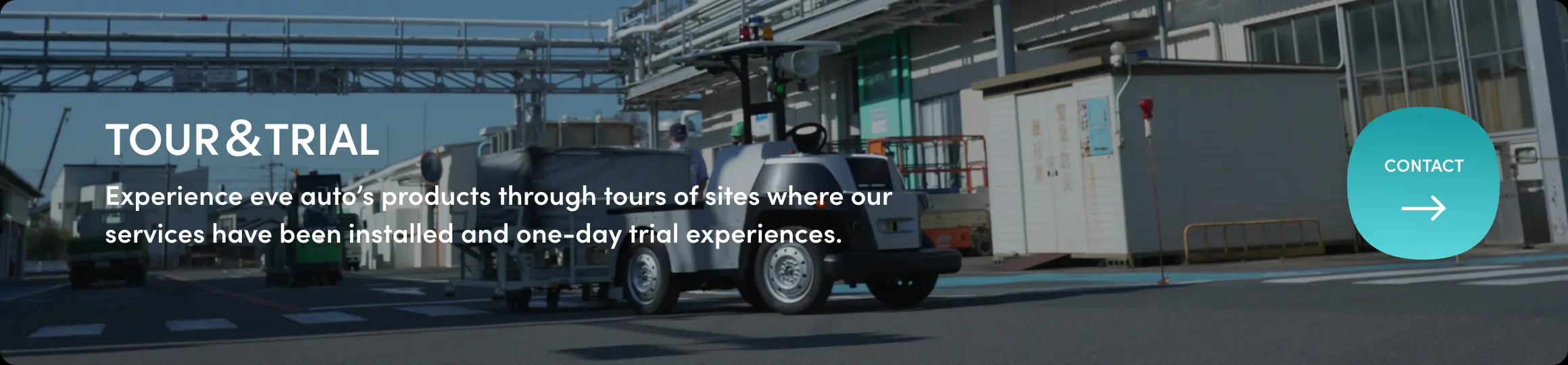

Provided automated transport of large, heavy items, such as refrigerated showcases, over a distance of 600 m between buildings

Customer’s requests

Customer’s requests

- We want to flexibly change routes.

- We want to automate the transport of large, heavy parts.

- We want to automate inter-building transfers within a large site.

eve autonomy’s solutions

eve autonomy’s solutions

This factory manufactures commercial refrigerators and refrigerated/freezer showcases, and uses manned forklifts and trucks to transport parts between buildings. We aim to reduce labor and safety risks associated with transporting large, heavy parts by replacing forklift transportation with the automated transport performed by eve auto.

Customer’s comments

Customer’s comments

Since the factory was aging and we were in the process of reforming our production system, the fact that we could freely change routes without having to draw guide lines was a deciding factor for the introduction of this system. The site is large, and the products being made are large, so transporting them between buildings was a challenge. Because eve auto is an unprecedented technology and service for us, and safety standards had not yet been determined, we were struggling to create such standards. Incorporating something new entails risk. By challenging ourselves to overcome the barriers between departments to achieve one major goal of improving the factory, we were able to clear these risks one by one and introduce the system.

Other cases