Manufacturing industry

Yamaha Motor Hamakita factory

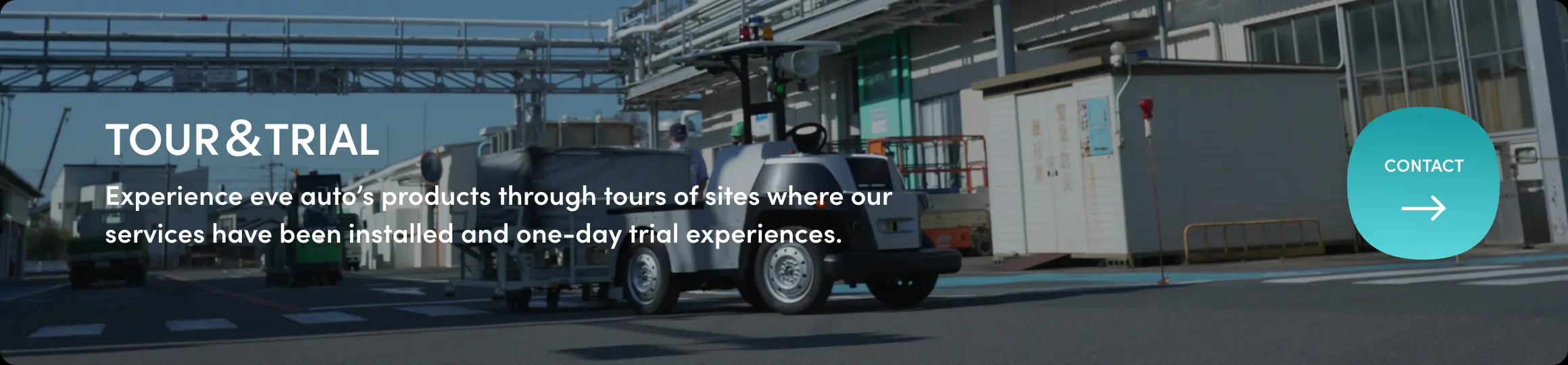

Provided automated transport of heavy items, such as crank shafts, over a distance of 700 m between buildings

Customer’s requests

Customer’s requests

- Automation of conveyance, especially for big and heavy products

- Seamless conveyance between outdoor and indoor

- Safety secured for cooperating people and vehicles in the factory

eve autonomy’s solutions

eve autonomy’s solutions

The object of automated conveyance is 1 ton of engine parts. It is used 10 times per one shift for a 700m route extending over both indoor and outdoor. Stability and robustness, namely eve’s distinctive feature realized autonomous driving even for this difficult route with gaps on rails at the entrance, slopes and bumpy roads with manholes. System cooperation with infrastructure has also been implemeted for signals at intersections, warning lights and shutters at the entrance.

Customer’s comments

Customer’s comments

The Hamakita factory produces connecting rods, crankshafts and gear parts. Conveyance of parts was operated by forklifts and tow cars because each production process (such as forging, machining, heat-treating and etc.) has been separated to several buildings. When we studied implementation of eve’s solution, there were various proposed sites and routes. Some people said it should be started from easier sites to implement, but we intentionally decided to start from much more difficult sites. This is because we thought the challenge at difficult environment should contribute to future implementation for other sites. In accordance with implementation, we improved the environment of logistics in the factory discussing with various related parties. Stock points in separated area have been centralized and lines of logistics flow have been leveled. It was tough to re-study the layouts and discuss many times with various parties in the factory because each building had different responsible persons. However, it was very helpful for us to change the route easily on eve’s system. It is so attractive to quickly repeat “Try & Error” in the short period to see which option is better for our operation. Now it is planned to develop new functions such as automation of onloading and offloading while we are preparing for night operation and additional autonomous vehicles to implement. New technology is not accepted quickly by many people. Therefore, we are pioneering as we can advise to other factories with many best practice at our factory.

Other cases