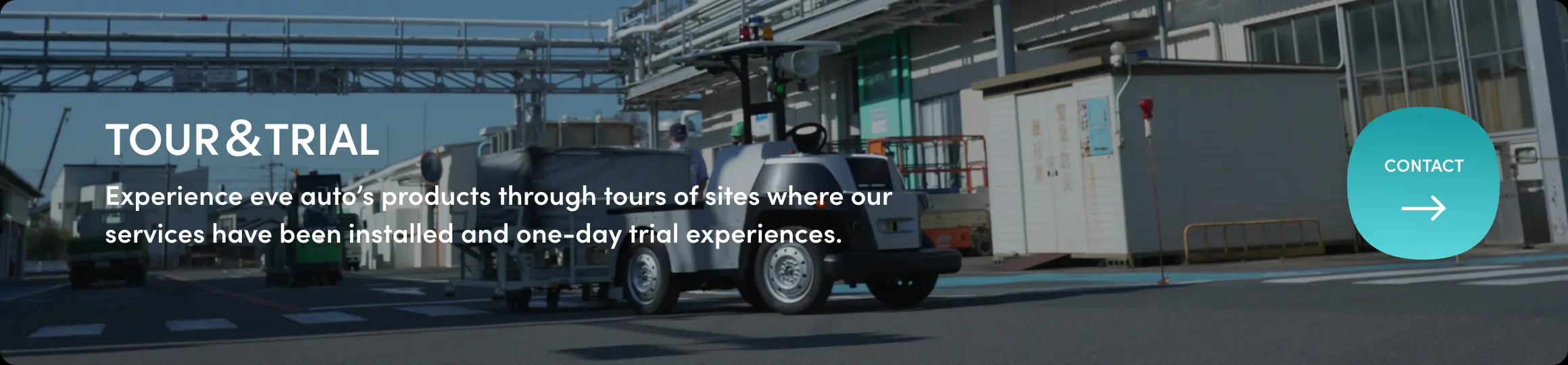

Petrochemicals

Prime Polymer Co., Ltd., Anesaki Works factory

Transport process of polypropylene resin samples Provided 1,800 hours of automated work per year

Customer’s requests

Customer’s requests

- We want to “try it out first” using agile development.

- We want it to run safely in the mixed traffic on our business premises.

- We want to pick up samples involving remote departures and multiple stops.

eve autonomy’s solutions

eve autonomy’s solutions

We have automated the process of transporting polypropylene resin samples, which are constantly being produced, to inspection sites, etc., approximately 1 km away from the production site. At the time of sample collection, an operator in the control building dispatches a vehicle to one of several stops using the fleet management system that is standard-packaged with the service. In addition, an infrastructure integration system (eve auto CONNECT) was used to operate a warning light placed indoors to come on when a vehicle arrives for inspection, etc.

Customer’s comments

Customer’s comments

When I wanted to promote digital transformation, the Digital and DTK Promotion Department of Idemitsu Kosan Co., Ltd. introduced me to eve auto. At first glance, I had a gut feeling that this was it. I could envision simple tasks being replaced by robots, and with the time saved, people could devote their time to creative work. Fortunately, our company had an environment that encourages agile implementation. The idea was to “try it out first, check it in detail, and eliminate issues one by one as they emerge.” This approach being compatible with the subscription-based service, which requires no construction work, was one of the reasons why we were able to quickly take on the challenge of automating outdoor transportation. Safety was the biggest concern when introducing the system. The Anesaki factory also handles hazardous materials, so we wondered if safe operation could be ensured in the mixed traffic within the plant. This issue was resolved when we were able to confirm the driving stability and safety through the test run. The fact that a special insurance policy for autonomous vehicles was included in the package was also a reassuring factor, as it would cover the vehicle in the event of an accident. We are beginning to feel a sense of relief as the risk of bicycle accidents, which sometimes occurred on dark roads at dawn, has been reduced. Our goal for the future is to automate a process that used to require people to perform about 30 transports every day, day and night, which would save about 5 hours of labor a day, or about 1,800 hours a year. We hope to use that time for other tasks to create added value and to use this as an opportunity to reform our manufacturing process.